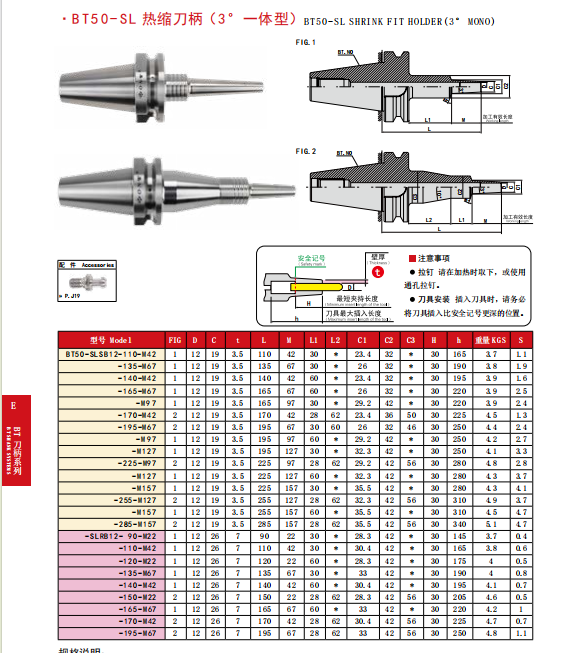

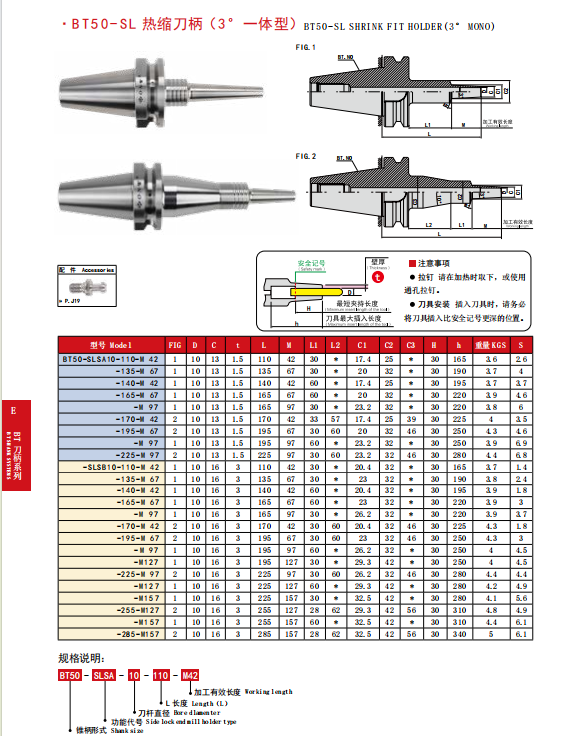

- PARAMETERS

- VEDIOS

Product Features and Applications of BT Heat Shrink Tool Holders

Product Features:

-

High Precision: BT heat shrink tool holders use heat shrink technology to ensure high-precision fitting between the tool and the holder, providing excellent radial and axial runout accuracy.

-

High Rigidity: With no gap between the tool and the holder, heat shrink tool holders offer extremely high rigidity, making them suitable for high-speed and high-load machining.

-

Quick Tool Change: Tools can be changed quickly through heating and cooling, improving production efficiency.

-

Good Balance: Heat shrink tool holders are precision dynamically balanced, making them suitable for high-speed machining and reducing vibration and noise.

-

Long Lifespan: Made from high-quality materials, they have a long service life and excellent wear resistance.

-

Wide Applicability: Suitable for various machining processes such as milling, drilling, and boring.

Applications:

-

High-Speed Machining: Suitable for high-speed milling, high-speed drilling, and other scenarios requiring high precision and rigidity.

-

Mold Manufacturing: In mold processing, BT heat shrink tool holders can provide high precision and high surface quality.

-

Aerospace: Used for machining high-strength materials in the aerospace industry, such as titanium alloys and composites.

-

Automotive Manufacturing: Suitable for high-precision machining of automotive components, such as engine blocks and gearboxes.

-

Precision Parts Machining: In industries like electronics and medical devices, BT heat shrink tool holders ensure high precision and surface quality in the machining of precision parts.